The “Sub-70 engine” at clinic check: the patient is well (and me too)!

During the last year and half I reached 50 hours of flight. Being that this is the cold season, it is the right moment to “admit the patient” to the Cors-Air Clinic for a complete check-up!

During this period I found very easy to take-off and land everywhere, also on little grass-fields slightly levelled, and the huge thrust of my big engine together the 14 sq m of the wing are assure very short take-off and high vertical speed. Very easy, but most importantly, a safety factor for the bush flying.

During this period I found very easy to take-off and land everywhere, also on little grass-fields slightly levelled, and the huge thrust of my big engine together the 14 sq m of the wing are assure very short take-off and high vertical speed. Very easy, but most importantly, a safety factor for the bush flying.

Actually, my little “bush-aircraft” is composed of the titanium Strike-T nanotrike (15 kg emergency included), the Cors-Air Black Bull engine (235 cc, manual, 17,5 kg with a carbon 130 cm prop) and the GRIF HS-14 wing (29 kg). Probably it is one of the more weight/thrust/performance ratio flying object. Surely, it is pure fun!

During the last one year and half, I cleaned the spark plug every three flights, checked the reduction belt tension and no more. I have not had any problems other than the loosening of the exaust connection and of the air box. Little problems rapidly solved just after landings, using the board tools.

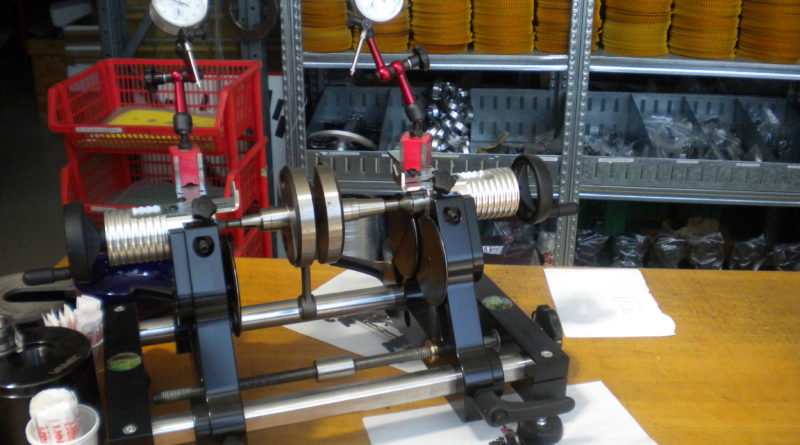

Reached the 50 hours, the Black Bull manual advice to substitute the spark-plug, the carburetor membranes and, if necessary, the reduction belt and the blades of the reed-valve system. Moreover, is necessary to control the air filter and the torque of nuts and bolts. But because I am not sure of the engine hours previous mine, we decided to do a 100 hours full inspection by putting of the engine on the operating table: open heart surgery on!

Reached the 50 hours, the Black Bull manual advice to substitute the spark-plug, the carburetor membranes and, if necessary, the reduction belt and the blades of the reed-valve system. Moreover, is necessary to control the air filter and the torque of nuts and bolts. But because I am not sure of the engine hours previous mine, we decided to do a 100 hours full inspection by putting of the engine on the operating table: open heart surgery on!

Observational phase: cylinder and piston are ok, no scratch, no heat heavy stain, just a thin carbonaceous film due to my typical rich carburation at low rpm. Ok, since we have opened the engine, it is a good idea to remove the carbon deposits! The piston rings are perfect but they are an old version, so we decide to replace them with the last model. All other parts are fine, the thoracic chest is in good conditions!

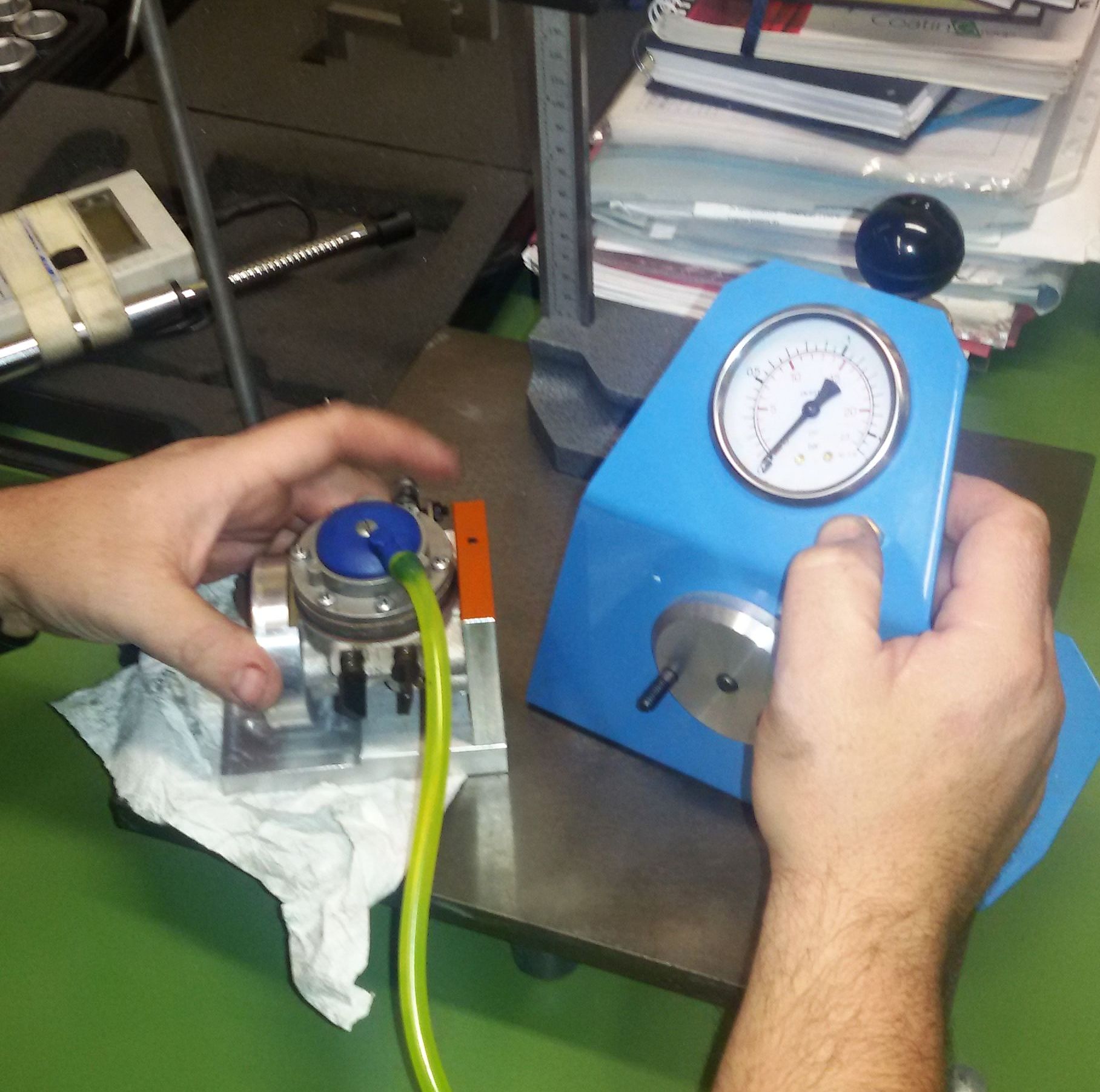

The Tryton carburetor has been opened, controlled and all membranes have been replaced. The carburetor is then reassembled and tested under pressure, in order to verify the correct opening of the fuel line. The air filter was replaced unlike the reed-valve system that is in excellent conditions. During these operations, the crankcase was subjected to a “washing shower” to ameliorate the engine look! The reduction belt is just a little bit worn-out, but I prefer to replace it too and to get one spare.

Ok, now is the time to “sew up the patient” and to verify the muscle-respiratory system: calibration of minimum rpm, control of carburation and thrust using the specific workbench: 85 kg/8300 rpm using 130 mm propeller with pitch 10. I am happy!

It remains to check the limbs health (the silent block) and the patient is able to return on his titanium trike. After a little bit more than two hours of work, the engine is almost new, I paid 163,00 Euro + VAT, that is about 3,50 Euro/h… Can I say viva the nanotrike? Let’s say it!

Now, it’s “the right time to put the legs under the table” and fill the stomach. With the help of a Lambrusco bottle of fine wine (you know the old Emilian tavern cookery? You should!) it’s easy to remember the past amazing flights and to plan new incredible adventures. Anyway, let’s wait for the Lambrusco effect to pass and then… we are ready!

On the working table, the younger brother of mine: the 125 cc Black Bee.